Introduction

In today’s interconnected world, global supply chains have become the backbone of modern business operations. The continuous advancement of technology, along with the rapid pace of globalization, has significantly transformed how products are sourced, manufactured, and distributed across borders. However, businesses now face more complexities than ever before. Geopolitical instability, supply chain disruptions, labor shortages, and climate change are just a few of the challenges that have intensified in recent years.

The COVID-19 pandemic further exposed the vulnerabilities of global supply chains and highlighted the need for greater resilience and adaptability. As businesses emerge from the disruptions caused by the pandemic, it’s clear that the future of supply chains will rely on new strategies, technologies, and innovative approaches to ensure continued efficiency and growth.

This article explores the current trends, challenges, and innovations in global enterprise supply chains, shedding light on how companies can adapt and thrive in the evolving landscape.

I. The Evolution of Global Supply Chains

- From Local to Global

- Historical Context: Historically, supply chains were often localized or regional, focusing on reducing costs within national borders. However, as globalization expanded, businesses began sourcing raw materials and components from different parts of the world, leading to longer and more complex supply chains.

- The Shift to Globalization: The shift to a globalized supply chain model allowed companies to reduce costs significantly, gain access to new markets, and leverage the comparative advantage of different regions. However, this also introduced new risks and dependencies.

- Technological Advancements

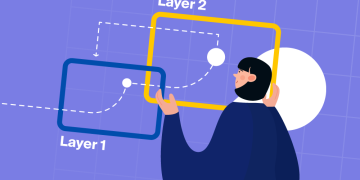

- The advent of the internet, cloud computing, and advanced data analytics has revolutionized supply chain management. Technologies like Enterprise Resource Planning (ERP) systems, blockchain, and the Internet of Things (IoT) have allowed businesses to gain more visibility, improve efficiency, and enhance the overall management of their supply chains.

- Impact of Global Events

- Events such as natural disasters, geopolitical tensions, and pandemics have highlighted the fragility of global supply chains. The COVID-19 pandemic was a significant event that forced many companies to rethink their supply chain structures and practices, demonstrating the need for better resilience and risk management.

II. Key Trends Shaping Global Supply Chains

- Resilience and Risk Management

- Post-Pandemic Strategies: The pandemic exposed critical vulnerabilities in supply chains, leading many companies to prioritize resilience in their strategies. Businesses are now focusing on building more flexible and adaptive supply chains that can withstand disruptions, whether caused by pandemics, natural disasters, or geopolitical tensions.

- Supply Chain Visibility: To improve resilience, companies are investing in technologies that provide real-time data and visibility across their entire supply chain. Greater transparency enables companies to identify problems faster, reduce lead times, and optimize inventory.

- Sustainability and Green Supply Chains

- As global awareness of environmental issues grows, sustainability has become a key focus for companies. Sustainable supply chains aim to reduce carbon footprints, minimize waste, and promote the use of renewable resources.

- Circular Economy: One of the major shifts in supply chain management is the movement towards a circular economy, where products are reused, repaired, or recycled instead of disposed of. Companies are adopting circular principles to reduce waste and improve the sustainability of their supply chains.

- Digital Transformation and Automation

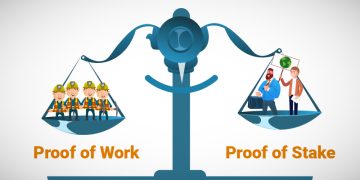

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms are being used to predict demand, optimize delivery routes, and automate various processes within supply chains. These technologies are enhancing decision-making capabilities and improving forecasting accuracy.

- Robotics and Automation: Automation is becoming increasingly common in warehouses and distribution centers. Robots are used for tasks like sorting, packaging, and transporting goods, helping companies improve efficiency and reduce operational costs.

- Blockchain: Blockchain technology is enabling greater transparency and security in supply chains. By providing immutable records of transactions, blockchain enhances traceability, reduces fraud, and ensures compliance, especially in cross-border transactions.

- Nearshoring and Regionalization

- Shifting Away from China: In response to rising trade tensions and the pandemic, many companies are reconsidering their reliance on distant suppliers, particularly in China. Nearshoring, or relocating production closer to key markets, is gaining traction as businesses aim to reduce transportation costs, minimize risks, and improve delivery times.

- Regional Trade Agreements: New regional trade agreements, such as the Regional Comprehensive Economic Partnership (RCEP) and USMCA, are encouraging companies to diversify their supply chains and explore opportunities closer to home, particularly in Asia and Latin America.

III. Major Challenges Facing Global Supply Chains

- Geopolitical Instability

- Trade wars, tariffs, and political tensions can disrupt global supply chains. The U.S.-China trade war highlighted how shifts in trade policy can affect manufacturing decisions and supply chain costs. Additionally, ongoing tensions in regions like the South China Sea, Eastern Europe, and the Middle East create uncertainty for companies reliant on global trade routes.

- Supply Chain Disruptions

- Natural Disasters and Climate Change: Natural disasters like hurricanes, floods, and wildfires pose a significant risk to supply chains, particularly those reliant on manufacturing or agriculture. The growing impact of climate change is expected to intensify these disruptions.

- Pandemics and Health Crises: The COVID-19 pandemic severely disrupted global supply chains, causing factory shutdowns, transportation delays, and labor shortages. While businesses are adapting to these challenges, the long-term impacts of the pandemic are still being felt.

- Labor Shortages and Workforce Challenges

- A shortage of skilled workers in key industries like manufacturing and logistics is a growing concern. In developed countries, an aging workforce combined with fewer younger workers entering the industry is exacerbating the problem.

- While automation and robotics offer potential solutions, there are challenges related to integrating these technologies, retraining workers, and managing potential job displacement.

- Cybersecurity Threats

- As supply chains become more digital, the risk of cyberattacks has increased. Ransomware, data breaches, and supply chain attacks are becoming more common, putting sensitive company data and critical infrastructure at risk.

- Protecting against cyber threats is now a top priority, with many businesses investing in cybersecurity solutions and ensuring their third-party suppliers adhere to strict security protocols.

IV. Innovations and Technologies Revolutionizing Supply Chains

- Internet of Things (IoT)

- IoT devices are increasingly used to monitor and track goods in real-time. Sensors can provide updates on the status and location of products, monitor temperature-sensitive goods, and even predict when maintenance is needed on equipment. This real-time visibility enables better decision-making and helps companies react more quickly to disruptions.

- Autonomous Vehicles and Drones

- Autonomous Trucks: Self-driving trucks are expected to revolutionize long-haul freight by reducing labor costs and increasing efficiency. Companies like Tesla and Waymo are leading the way in developing autonomous vehicles for the logistics industry.

- Drones: Drones are increasingly being used for last-mile delivery, particularly in urban areas. This technology promises to speed up delivery times, reduce costs, and improve customer satisfaction.

- Artificial Intelligence and Machine Learning

- Demand Forecasting: AI and ML algorithms are used to predict demand patterns, helping businesses better manage inventory and optimize supply chain operations.

- Warehouse Automation: AI-powered robots are now capable of performing tasks like sorting, packing, and transporting goods in warehouses, significantly improving operational efficiency.

- Supply Chain Optimization: AI is also being used to optimize transportation routes, reducing fuel consumption and delivery times.

- Blockchain for Transparency

- Blockchain technology offers a secure and transparent way to track goods across the supply chain. Each transaction is recorded on a decentralized ledger, making it easier to trace products and ensure compliance with regulations.

- Use Case: Companies like Walmart and IBM are using blockchain to trace food products from farm to store, enhancing food safety and providing consumers with greater confidence in the products they purchase.

V. The Future of Global Supply Chains

- Hyper-Personalization

- As consumer preferences shift toward more personalized products, companies are adapting their supply chains to provide greater flexibility and customization. Technologies like 3D printing and on-demand manufacturing will play a critical role in this transformation.

- Supply Chain as a Service (SCaaS)

- More businesses are outsourcing supply chain functions to third-party providers, leading to the rise of Supply Chain as a Service (SCaaS). This allows companies to focus on their core competencies while relying on specialized partners to manage logistics, inventory, and procurement.

- The Role of Artificial Intelligence

- The future of supply chains will be heavily influenced by AI, with applications ranging from demand forecasting and predictive maintenance to autonomous vehicles and robots. Companies that successfully leverage AI will gain a competitive edge in terms of efficiency and customer satisfaction.

Conclusion

The global enterprise supply chain landscape is evolving rapidly. From building resilience to adopting cutting-edge technologies like AI, blockchain, and IoT, businesses are finding innovative ways to overcome the challenges of modern supply chains. However, to remain competitive, companies must stay agile and proactive, continuously improving their supply chain strategies to meet the demands of the future.

By embracing technological advancements and focusing on sustainability and risk management, businesses can navigate the complexities of the global supply chain and thrive in an increasingly interconnected world.