The modern business landscape is shaped by global interconnectedness, but it is also increasingly vulnerable to disruptions caused by geopolitical tensions, pandemics, trade wars, natural disasters, and economic uncertainties. In this environment, businesses must develop supply chains that are not only efficient but also resilient, flexible, and capable of responding to unpredictable crises. To achieve this, companies are embracing strategies such as diversifying supply sources, increasing localized production, and implementing robust risk management frameworks. This article explores these strategies in depth, discussing their implementation, benefits, and real-world applications in strengthening supply chain resilience.

1. The Growing Importance of Supply Chain Resilience

The term “supply chain resilience” has gained significant traction in recent years, especially in light of disruptions such as the COVID-19 pandemic, Brexit, and the trade war between the U.S. and China. A resilient supply chain is one that can anticipate, respond to, and recover from disruptions without significant loss in performance or profitability. Unlike traditional supply chains, which focus primarily on efficiency and cost minimization, resilient supply chains emphasize flexibility, redundancy, and adaptability.

To achieve resilience, companies must adopt strategies that allow them to mitigate risks and adapt quickly to unforeseen events. By diversifying suppliers, localizing production, and developing comprehensive risk management frameworks, businesses can ensure that their supply chains are robust enough to withstand future global crises or geopolitical risks.

2. Diversifying Supply Sources: Reducing Dependency on Single Suppliers

2.1 The Risks of Single-Source Dependence

Historically, businesses have often favored single-source suppliers for their efficiency and cost-effectiveness. However, over-reliance on a single supplier or region can expose companies to substantial risks in times of geopolitical instability, natural disasters, or pandemics. For instance, the 2020 pandemic highlighted the vulnerabilities of global supply chains heavily reliant on China as the primary source of manufacturing and raw materials. When the country experienced lockdowns, businesses worldwide faced supply shortages, increased costs, and delayed deliveries.

2.2 Benefits of Supply Source Diversification

Supply diversification refers to the practice of sourcing materials, products, or services from multiple suppliers across different regions. It reduces the risks of dependence on a single supplier and helps mitigate the impact of disruptions. The key benefits include:

- Risk Mitigation: By engaging with multiple suppliers, businesses can ensure a steady flow of materials even if one supplier or region faces disruptions.

- Cost Optimization: Different regions or suppliers may offer competitive pricing or lower production costs, giving businesses the opportunity to optimize costs.

- Increased Flexibility: With multiple suppliers in various regions, companies can easily switch suppliers or routes if one becomes unavailable, improving supply chain flexibility.

2.3 Implementing Supply Diversification

To effectively diversify supply sources, businesses can take the following steps:

- Geographical Diversification: Establish a network of suppliers across multiple regions or countries. For example, companies sourcing from Asia can also explore suppliers in Europe, Africa, or North America.

- Strategic Sourcing: Companies should differentiate between critical and non-critical materials. For mission-critical products or components, diversify suppliers further and create backup suppliers in case of emergencies.

- Supplier Evaluation: Regularly evaluate suppliers based on their stability, ability to scale, and geographical risks. In times of crisis, it is essential to have a list of trusted backup suppliers that can step in immediately.

3. Localizing Production: Decreasing Dependency on Long Supply Chains

3.1 What is Localized Production?

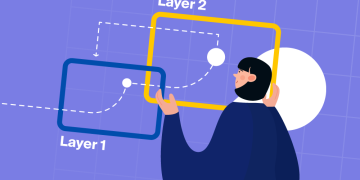

Localized production involves moving manufacturing processes closer to the end consumer or shifting production facilities from low-cost countries back to higher-cost regions. This strategy contrasts with traditional models where production is concentrated in low-cost regions (such as China, India, or Vietnam) due to the cost savings in labor and materials.

3.2 The Importance of Localized Production in Resilience

By localizing production, businesses reduce their exposure to the risks associated with long and complex global supply chains. The key benefits include:

- Faster Response Times: Localized production enables faster lead times and delivery speeds, allowing businesses to respond more quickly to changes in demand or market conditions.

- Lower Transportation Costs: With production closer to key markets, businesses can reduce transportation costs and eliminate risks associated with shipping delays or disruptions.

- Reduced Exposure to Global Risks: Local production limits the impact of global disruptions, such as international shipping delays, tariff changes, or geopolitical tensions.

3.3 Implementing Localized Production

Companies can take several approaches to localize production:

- Establish Regional Manufacturing Centers: Instead of relying solely on overseas production, companies can establish regional hubs that cater to specific markets. For instance, automobile manufacturers may set up plants in Mexico for the U.S. market, or European companies may set up manufacturing units in Eastern Europe.

- Nearshoring vs. Offshoring: Nearshoring is the practice of moving production closer to home markets, typically to neighboring or nearby countries. This reduces transportation time and costs while maintaining cost advantages. For example, U.S. companies may nearshore production to Mexico or Central America to be closer to the U.S. market.

- Flexible Production Systems: Adopt production processes that are adaptable and capable of switching between products or scaling up production as demand changes. Modular production and 3D printing are examples of adaptable systems.

4. Implementing a Risk Management Framework: Identifying, Mitigating, and Responding to Risks

4.1 The Role of Risk Management in Supply Chain Resilience

A robust risk management framework is essential for identifying, assessing, and responding to potential risks in the supply chain. Companies that prioritize risk management can not only identify vulnerabilities but also create strategies to mitigate and manage those risks effectively.

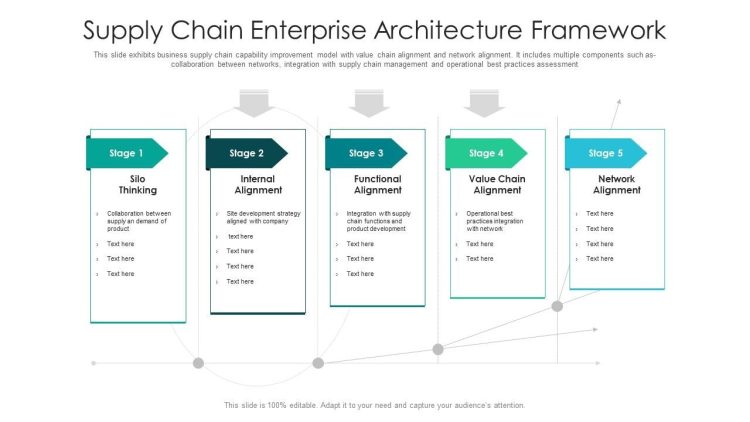

4.2 Key Components of a Risk Management Framework

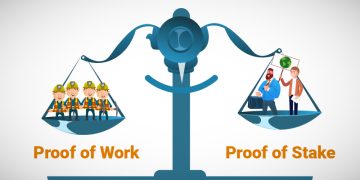

The core components of a risk management framework for supply chains include:

- Risk Identification: Recognizing potential risks in the supply chain, including geopolitical risks, supply disruptions, natural disasters, and economic shifts.

- Risk Assessment: Evaluating the likelihood of risks occurring and the potential impact they could have on the business. This involves quantifying risks in terms of their financial and operational consequences.

- Risk Mitigation: Developing strategies to reduce the probability of risks occurring, such as establishing backup suppliers, redundant transportation routes, or security protocols.

- Crisis Management and Recovery: Creating a business continuity plan that outlines specific actions to take in the event of a disruption, including inventory buffers, alternate suppliers, and alternative logistics routes.

4.3 Building a Resilient Risk Management System

To build an effective risk management framework, companies should:

- Perform Regular Risk Assessments: Assess risks regularly through scenario planning, stress tests, and simulations of worst-case scenarios.

- Develop Contingency Plans: Prepare comprehensive contingency plans that cover supply chain disruptions, geopolitical events, or natural disasters.

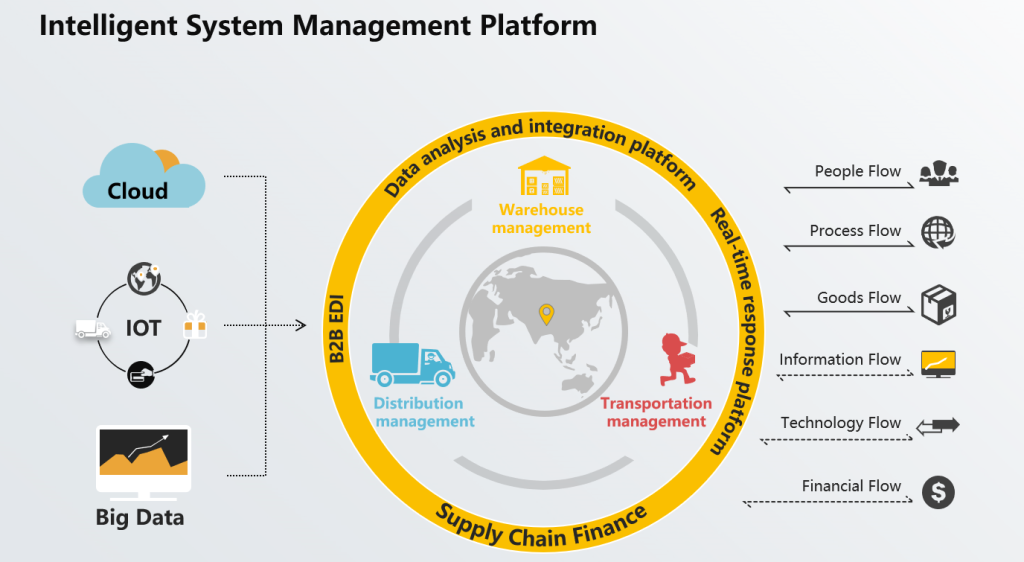

- Leverage Technology: Implement technologies like AI, IoT, and blockchain to monitor risks in real time. For instance, AI-driven predictive analytics can help identify potential supply chain risks by analyzing data patterns and trends.

- Establish Communication Protocols: Ensure clear communication channels with key stakeholders, including suppliers, customers, and logistics providers, so they can respond quickly in times of crisis.

5. Real-World Case Studies: Diversification, Localization, and Risk Management in Action

5.1 Apple Inc.

Apple has long been known for its diverse supply chain and localization strategies. In response to disruptions like COVID-19, Apple increased production in India, Vietnam, and other countries to reduce reliance on its traditional manufacturing base in China. Furthermore, the company has created backup suppliers for key components like semiconductors and display panels, ensuring that any disruption in one region doesn’t cripple its entire supply chain.

5.2 Toyota

Toyota’s commitment to risk management was evident during the 2011 earthquake and tsunami in Japan. The company had a well-established supply chain risk framework, which allowed it to quickly assess the impact of the disaster on its suppliers and take necessary actions. Toyota also adopted the “just-in-case” inventory strategy, maintaining larger stocks of critical parts to protect against potential disruptions.

6. Conclusion: Building Future-Proof Supply Chains

As the global landscape continues to evolve, businesses must focus on building flexible, resilient supply chains that can withstand geopolitical risks, economic shifts, and unforeseen crises. By diversifying supply sources, localizing production, and implementing comprehensive risk management frameworks, companies can not only safeguard their operations against disruptions but also enhance their long-term competitiveness. These strategies, when implemented correctly, offer businesses the agility to adapt quickly to changing circumstances while ensuring a stable flow of goods and services in an increasingly unpredictable world.

Through proactive planning and adaptability, businesses can successfully navigate