1. Introduction: The Need for Real-time Tracking in the Modern Supply Chain

The traditional supply chain model relies heavily on manual processes, paper-based documentation, and time-consuming coordination between various parties involved. However, this outdated system often results in delays, inefficiencies, and a lack of transparency, making it difficult for businesses to monitor the movement of goods in real time. Additionally, the increasing complexity of global supply chains—spanning multiple countries, suppliers, and transportation modes—further exacerbates these issues.

Real-time tracking of goods, which allows businesses to monitor the entire journey of products from raw materials to the final consumer, offers an innovative solution to these challenges. By digitizing the supply chain and incorporating technologies like Blockchain, IoT, and AI, companies can ensure better transparency, traceability, and accountability, leading to enhanced operational efficiency and improved customer satisfaction.

2. The Evolution of Supply Chain Tracking

2.1 Traditional Supply Chain Management: Challenges and Limitations

In traditional supply chain systems, businesses rely on a series of disconnected systems and manual tracking methods to monitor product movements. This process is often time-consuming, error-prone, and susceptible to fraud. Some of the key challenges of traditional supply chain management include:

- Lack of Visibility: Companies are often unable to track the movement of goods in real time, making it difficult to predict delays or resolve issues quickly.

- Fraud and Counterfeiting: Without a secure, verifiable system to track the authenticity of goods, supply chains are vulnerable to fraud, counterfeiting, and the circulation of substandard products.

- Inefficiency: Due to the lack of automation, manual processes such as paperwork, phone calls, and emails can lead to delays and higher operational costs.

2.2 The Digital Transformation of Supply Chains

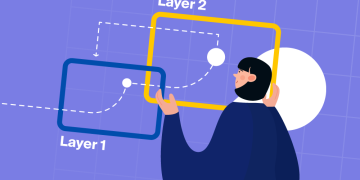

With the advent of digitization and automation, businesses are increasingly adopting advanced technologies to streamline supply chain operations. Real-time tracking, enabled by technologies such as IoT sensors, Blockchain, and cloud computing, is at the forefront of this transformation. These innovations provide the ability to capture data at every stage of the supply chain and share it seamlessly between stakeholders.

For example, a smart RFID tag or QR code attached to a product can provide real-time updates on its location, condition, and status throughout its journey, from the manufacturer to the final point of sale. By collecting and sharing this data through digital platforms, companies can gain unprecedented visibility into their supply chains and make informed decisions to improve operations.

3. Real-time Tracking Technologies: Blockchain, IoT, and AI

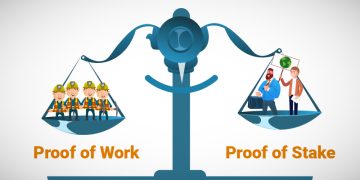

3.1 Blockchain Technology: Ensuring Transparency and Security

One of the most powerful technologies enabling real-time tracking in supply chains is Blockchain. Blockchain is a distributed ledger that records transactions in a secure, immutable, and transparent manner. Each transaction or data entry is encrypted and timestamped, and once recorded, it cannot be altered or deleted. This immutability and transparency make Blockchain ideal for tracking the flow of goods across complex supply chains.

Key Benefits of Blockchain for Real-time Supply Chain Tracking:

- Immutable Record: Blockchain ensures that all transactions are securely recorded, providing an unchangeable history of the product’s journey, from raw materials to the final consumer.

- Transparency: Blockchain’s decentralized nature means that every stakeholder—whether a supplier, manufacturer, distributor, or retailer—can access the same real-time data, enhancing collaboration and trust.

- Reduced Fraud and Counterfeiting: Blockchain’s secure, transparent nature helps ensure the authenticity of products, reducing the risk of counterfeiting and fraud.

- Improved Efficiency: By automating the process of recording and verifying transactions, Blockchain eliminates the need for manual data entry, reducing errors and inefficiencies.

Several companies, including Walmart, IBM, and Maersk, have implemented Blockchain-based traceability systems to enhance transparency and track the movement of products in real-time.

3.2 Internet of Things (IoT): Real-time Data Collection and Monitoring

The Internet of Things (IoT) refers to the network of interconnected devices that collect, transmit, and exchange data. In the context of supply chain management, IoT sensors and devices play a critical role in enabling real-time tracking of goods. These sensors can be attached to products, containers, pallets, or vehicles to capture data on location, temperature, humidity, and other environmental factors that affect the quality and condition of the goods.

Key Applications of IoT in Supply Chain Tracking:

- Tracking the Movement of Goods: GPS-enabled devices and RFID tags can track the real-time location of goods as they move through the supply chain, providing businesses with valuable insights into the progress of their shipments.

- Monitoring Environmental Conditions: IoT sensors can monitor environmental factors such as temperature, humidity, and light exposure. This is particularly important for industries like food and pharmaceuticals, where product quality is highly sensitive to environmental changes.

- Predictive Maintenance: IoT devices embedded in vehicles or machinery can monitor equipment performance and predict maintenance needs, reducing downtime and optimizing operational efficiency.

- Enhanced Data Analytics: IoT devices generate vast amounts of data that can be used for advanced data analytics. By leveraging this data, businesses can gain insights into supply chain bottlenecks, inventory levels, and consumer demand patterns.

3.3 Artificial Intelligence (AI) and Machine Learning: Optimizing Supply Chain Decisions

Artificial Intelligence (AI) and Machine Learning (ML) algorithms can be applied to real-time supply chain data to optimize decision-making and improve operational efficiency. AI can analyze large datasets to identify patterns, predict demand, and automate routine tasks, allowing companies to make better, data-driven decisions.

Key Applications of AI in Real-time Tracking:

- Demand Forecasting: AI algorithms can analyze historical data and real-time market trends to predict future demand for products, allowing businesses to optimize inventory levels and reduce the risk of stockouts or overstocking.

- Supply Chain Optimization: AI can optimize the routing and scheduling of shipments, ensuring that goods are delivered on time and at the lowest possible cost.

- Real-time Risk Management: AI systems can assess potential risks in the supply chain, such as disruptions caused by weather, political events, or supplier issues. By identifying these risks in real time, businesses can take proactive measures to mitigate their impact.

4. Benefits of Real-time Tracking for Enterprises

4.1 Improved Operational Efficiency

By implementing real-time tracking systems, businesses can automate routine processes, reduce manual work, and minimize human error. This leads to enhanced operational efficiency, reduced lead times, and more effective inventory management. Businesses can also optimize their production schedules and distribution routes, leading to cost savings and improved resource allocation.

4.2 Increased Transparency and Trust

Real-time tracking provides transparency at every stage of the supply chain, allowing businesses to ensure that products are sourced ethically and sustainably. Blockchain technology, in particular, plays a significant role in building trust between stakeholders, as all parties have access to the same real-time data. This level of transparency can also improve consumer confidence, as customers can track the journey of their products and verify their authenticity.

4.3 Enhanced Customer Experience

With real-time tracking, businesses can provide customers with accurate and up-to-date information about the status of their orders. This enhances the customer experience by offering visibility into delivery times and product quality. Real-time updates can also improve customer satisfaction by allowing businesses to resolve issues quickly and proactively.

4.4 Risk Mitigation and Compliance

Real-time tracking can help businesses identify potential risks and disruptions in their supply chains, such as delayed shipments or quality issues. By monitoring product conditions throughout the supply chain, companies can also ensure compliance with industry regulations and standards, particularly in sectors like pharmaceuticals, food, and electronics.

5. Challenges and Limitations of Real-time Tracking

While the benefits of real-time tracking are significant, businesses may face several challenges when implementing these systems:

- High Initial Investment: The cost of setting up real-time tracking systems, including IoT sensors, Blockchain infrastructure, and AI algorithms, can be substantial.

- Data Privacy and Security Concerns: The use of IoT and Blockchain technology requires the collection and sharing of large amounts of data. Businesses must ensure that sensitive information is protected against cyberattacks and unauthorized access.

- Interoperability: Different stakeholders in the supply chain may use various technologies and platforms. Ensuring seamless integration and interoperability between these systems is crucial for effective real-time tracking.

6. Conclusion: The Future of Real-time Tracking in Supply Chains

Real-time tracking represents a monumental shift in the way businesses manage their supply chains. By embracing technologies like Blockchain, IoT, and AI, companies can achieve enhanced visibility, improved efficiency, and greater transparency. While challenges remain, the benefits of real-time tracking are clear: better operational management, reduced fraud, optimized resources, and increased customer trust.

As supply chain technology continues to evolve, real-time tracking will become an essential tool for businesses looking to stay competitive in an increasingly globalized and complex market. The future of supply chain management lies in digital transformation, and real-time tracking is a cornerstone of that transformation.