Introduction

In recent years, blockchain technology has emerged as a transformative force across multiple industries, offering enhanced security, transparency, and efficiency. While blockchain is often associated with cryptocurrencies, its potential extends far beyond digital currencies. One of its most promising applications lies in its ability to optimize and streamline supply chain management. Supply chains are crucial to the functioning of businesses in sectors ranging from manufacturing to retail, and inefficiencies or disruptions within these chains can lead to significant financial losses.

For decades, companies have relied on traditional Enterprise Resource Planning (ERP) systems to manage and automate business processes. These ERP systems integrate various functions such as procurement, inventory management, and logistics, providing a unified platform for operations. However, traditional ERP systems have limitations when it comes to offering complete transparency, ensuring data integrity, and facilitating real-time tracking of goods and transactions across multiple stakeholders. This is where blockchain technology comes in.

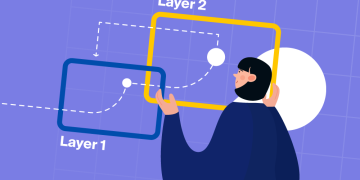

By integrating blockchain technology with existing ERP systems, companies can address these challenges and achieve new levels of visibility, security, and efficiency in their supply chain management. In this article, we will explore how blockchain can seamlessly integrate with traditional ERP systems and the benefits this integration brings to the supply chain.

Understanding ERP Systems and Supply Chain Management

What is ERP?

Enterprise Resource Planning (ERP) systems are software platforms that help organizations manage their core business processes in real time. An ERP system integrates a variety of functions including:

- Finance and Accounting

- Human Resources (HR)

- Procurement and Inventory

- Sales and Distribution

- Customer Relationship Management (CRM)

The aim of an ERP system is to provide a unified platform that allows organizations to manage their operations efficiently, reduce redundancies, and improve decision-making by offering a holistic view of business data.

Challenges in Supply Chain Management

Supply chain management (SCM) refers to the process of overseeing the production and movement of goods, from raw materials to final products delivered to consumers. SCM includes a wide range of activities, such as:

- Procurement of raw materials

- Manufacturing and assembly

- Storage and inventory management

- Distribution and logistics

- Retail and customer service

While traditional ERP systems have played a key role in managing these activities, there are several challenges that companies face in supply chain management:

- Lack of Transparency: ERP systems typically store data internally within an organization. As a result, stakeholders such as suppliers, distributors, and customers may have limited visibility into the status of the goods they are dealing with.

- Inefficiencies in Tracking: Tracking the movement of goods through the supply chain is often fragmented, leading to delays, errors, or the inability to quickly identify bottlenecks or disruptions.

- Data Integrity Issues: Traditional ERP systems rely heavily on centralized databases. Any errors or manipulations of data can compromise the integrity of the entire supply chain.

- Fraud and Counterfeit Risks: In some industries, especially in high-value sectors such as pharmaceuticals and luxury goods, the risk of fraud and counterfeit products is a significant concern. Traditional ERP systems are not always equipped to prevent or detect these risks.

Blockchain Technology: A New Approach to Supply Chain Management

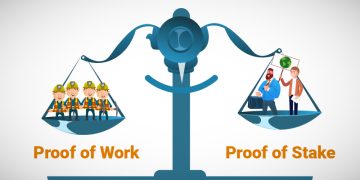

Blockchain is a decentralized, distributed ledger technology that records transactions across multiple computers in such a way that the registered transactions cannot be altered retroactively. This is achieved through cryptographic techniques that ensure data integrity, transparency, and security. The key features of blockchain that make it ideal for supply chain management include:

- Immutability: Once data is recorded on the blockchain, it cannot be changed or deleted. This provides a high level of security and guarantees that the recorded transactions are tamper-proof.

- Transparency: Blockchain allows for transparent tracking of all transactions, providing a clear and verifiable record of goods as they move through the supply chain.

- Decentralization: Rather than relying on a single centralized authority, blockchain operates on a distributed network of nodes. This decentralization ensures that no single party has full control over the data, reducing the risk of fraud or manipulation.

- Real-Time Updates: With blockchain, all parties involved in the supply chain can access the same up-to-date data, ensuring that everyone is on the same page. This enables faster decision-making and quicker responses to disruptions or changes.

The Benefits of Integrating Blockchain with ERP Systems in Supply Chain Management

When combined with ERP systems, blockchain can significantly enhance the capabilities of supply chain management. Below are some of the key benefits of integrating blockchain with traditional ERP systems:

1. Improved Transparency and Visibility

One of the most significant advantages of blockchain is its ability to provide end-to-end transparency in the supply chain. Traditional ERP systems are often siloed, with each organization maintaining its own set of data that may not be shared across the network. Blockchain, on the other hand, creates a shared, immutable ledger where every transaction is visible to all authorized parties.

By integrating blockchain into an ERP system, organizations can provide real-time visibility to all stakeholders, including suppliers, distributors, and customers. This helps in tracking the status of goods, verifying their provenance, and ensuring that the entire supply chain is compliant with industry standards.

For example, in the food industry, blockchain integration can enable consumers to trace the journey of their food products from farm to table. With blockchain’s transparent ledger, they can see when and where the product was grown, how it was processed, and whether it was handled according to safety standards.

2. Enhanced Data Integrity and Security

Data integrity is critical in supply chain management. Traditional ERP systems store data in centralized databases, making them vulnerable to cyber-attacks, human errors, and data manipulation. If a hacker gains access to the system, they can potentially alter crucial supply chain data, leading to fraud, theft, or errors.

Blockchain addresses this problem by providing a decentralized, cryptographically secure environment for data storage. Every transaction recorded on the blockchain is timestamped and cryptographically sealed, ensuring that it cannot be tampered with. Moreover, the data is stored across multiple nodes in the network, making it resistant to hacking or data breaches.

When integrated with ERP systems, blockchain ensures that the data within the system is trustworthy and verifiable, helping businesses maintain the integrity of their supply chains.

3. Faster and More Efficient Transactions

Blockchain can automate several aspects of supply chain management, reducing the time and effort required to complete transactions. Smart contracts, for instance, are self-executing contracts with predefined conditions that automatically execute when those conditions are met. By using smart contracts, companies can automate processes like payments, inventory management, and order fulfillment.

For example, a smart contract could be set up to automatically release payment to a supplier once a shipment has arrived at a designated warehouse, thus speeding up the process and eliminating the need for manual intervention. This is particularly valuable in global supply chains where multiple intermediaries are involved, and delays are common.

By integrating smart contracts with traditional ERP systems, businesses can automate complex workflows and reduce the risk of human error, resulting in faster, more efficient operations.

4. Reducing Fraud and Counterfeit Products

One of the most significant risks in the supply chain is the threat of counterfeit goods. In industries like pharmaceuticals, electronics, and luxury goods, counterfeit products can be harmful to consumers and damaging to a brand’s reputation.

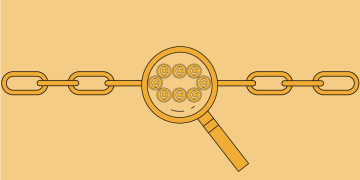

Blockchain’s transparent and immutable ledger can help track the authenticity of products throughout the supply chain. By recording each step of the product’s journey, from manufacturing to delivery, blockchain provides an auditable trail that can be used to verify the legitimacy of goods.

For example, luxury goods brands can use blockchain to create unique digital certificates of authenticity for each product. This digital record can be linked to the product and verified by consumers and retailers, reducing the risk of counterfeit products entering the market.

5. Reducing Supply Chain Costs

Integrating blockchain with ERP systems can also help reduce supply chain costs. Blockchain eliminates the need for intermediaries in the supply chain, such as banks, clearinghouses, and third-party logistics providers. By creating a decentralized platform for transaction verification and settlement, blockchain reduces the overhead costs associated with these intermediaries.

Moreover, blockchain’s ability to streamline and automate processes like invoicing, payments, and shipment tracking can reduce operational costs and eliminate inefficiencies. With fewer intermediaries and greater automation, supply chain operations become leaner and more cost-effective.

Use Cases for Blockchain Integration with ERP Systems

Several industries are already exploring the potential of integrating blockchain with ERP systems to optimize supply chain management. Below are a few real-world examples:

1. Automotive Industry

The automotive industry relies on a complex network of suppliers, manufacturers, and distributors. Blockchain can help companies like BMW and Ford improve traceability and transparency in the supply chain. For instance, blockchain can track the provenance of parts used in the production of vehicles, ensuring that only genuine, high-quality components are used.

2. Pharmaceuticals

In the pharmaceutical industry, blockchain can be used to ensure the authenticity of drugs and prevent counterfeit products from entering the market. Companies like Pfizer are experimenting with blockchain to create tamper-proof records of drug shipments, making it easier to trace drugs from manufacturer to consumer.

3. Food and Agriculture

Blockchain’s ability to improve transparency is particularly valuable in the food industry, where safety is a primary concern. Companies like Walmart and Nestlé have partnered with blockchain providers to track the journey of food products from farm to table. Blockchain ensures that consumers can trace the origin and quality of their food, providing greater confidence in the safety of the products they consume.

4. Retail and E-Commerce

Retail giants like Amazon and Alibaba are exploring how blockchain can optimize their supply chains. By integrating blockchain with their ERP systems, they can offer consumers greater transparency and faster delivery times while reducing costs

and improving operational efficiency.

Conclusion

Integrating blockchain technology with traditional ERP systems presents a powerful opportunity to optimize supply chain management. By improving transparency, data integrity, transaction speed, and security, blockchain can address the longstanding challenges of supply chain inefficiencies and fraud. The ability to track and verify goods in real-time offers businesses new ways to enhance customer trust, reduce costs, and streamline operations. As blockchain technology continues to evolve, its integration with ERP systems will play a pivotal role in shaping the future of global supply chains, offering companies a competitive edge in an increasingly digital and interconnected world.